Automation in manufacturing is like the behind-the-scenes maestro of a big concert, making sure everything runs smoothly. But the conductor, while essential, can only do so much without the right instruments in the hands of talented musicians – your manufacturing team.

Picture this: a skilled musician attempting to create a symphony with a broken violin. The strings are frayed, the bow is worn, and the sound it produces is, well, less than harmonious.

It’s a struggle, to say the least.

In the world of manufacturing, your team is like that musician, and their tools are the instruments they use to create their symphony of production.

Now, imagine if those tools were outdated, clunky, and just not up to the task. The result? A discordant cacophony rather than a smooth and beautiful performance.

In truth, the tools they have in their hands are more suited for the history books than for the present moment. But, with the right modern tools, you can transform your team’s potential with the help of automation in manufacturing.

In this blog, we’re delving into the significance of modern tools and automation in manufacturing businesses, particularly for Small to Medium Manufacturing Enterprises (SMEs). As a business owner, it’s essential to understand that the right tools can be the game-changer your team needs.

What is the Impact of Outdated Tools on Employees?

Outdated tools can have a significant impact in the world of automation in manufacturing. They aren’t just a minor inconvenience; they’re the invisible roadblocks that hinder your team’s performance and, consequently, your business’s growth.

When teams are saddled with obsolete equipment, they can’t perform at their best, leading to missed opportunities, inefficiencies, and frustration.

Productivity takes a substantial hit, and those repetitive, time-consuming tasks that everyone dreads? Outdated tools often make them even more painful. They slow down operations, introduce errors, and leave your team yearning for more efficient ways to complete their work.

However, the impact goes beyond productivity. Outdated tools can be demotivating. When your team is provided with a set of outdated tools, they’re likely to lose some of their mojo. This lack of motivation can drain their enthusiasm and job satisfaction and even lead to higher employee turnover rates, which is detrimental to any business.

And that’s where modern tools come to the rescue. These tools can be a game-changer for automation in manufacturing, as they streamline tasks, foster innovation, boost motivation, and ultimately lead to higher productivity and better results for your business.

How Do Modern Tools Enhance Automation in Manufacturing?

Automation in the manufacturing industry represents a significant advancement in efficiency, precision, and productivity. Imagine it as the central nervous system of your manufacturing operation, seamlessly connecting various components to optimise the production process.

However, the effectiveness of automation heavily depends on the quality of the tools available to your manufacturing team.

Modern tools are the precision instruments that elevate the performance of the entire system. They are akin to high-tech gadgets and machinery that streamline and optimise each step of the manufacturing business process automation.

These tools complement the speed of automation, ensuring that your team operates at peak efficiency and flexibility.

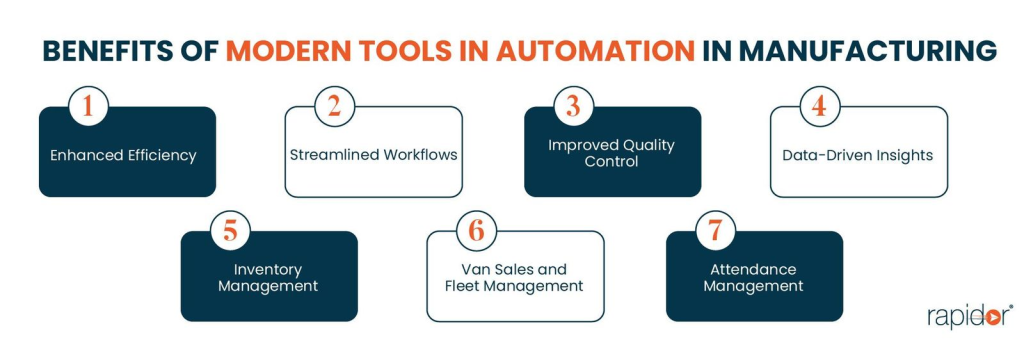

What are the Benefits of Modern Tools in Automation in Manufacturing?

The combination of automation and modern tools in the manufacturing business can be a game-changer. These tools are not just fancy additions; they bring many benefits that can transform your business operations.

Here’s a concise list of advantages that these tools bring:

- Enhanced Efficiency: Modern tools, including business management software, allow for faster and more precise execution of tasks, reducing downtime and minimising errors in the automation of the manufacturing process.

- Streamlined Workflows: Tools like sales and inventory management systems seamlessly integrate your sales and stock management, automating tasks and reducing the burden of manual labour. This ensures that your team can focus on critical aspects of production.

- Improved Quality Control: Manufacturing software solutions provide real-time quality control, ensuring that products meet your standards consistently. This is vital for maintaining customer satisfaction and reducing defects.

- Data-Driven Insights: Modern tools offer data analytics capabilities, which can provide valuable insights into your automation in manufacturing processes. This data can be used for continuous improvement and decision-making. Procurement optimization can be achieved by analysing data.

- Inventory Management: Stock management software tools keep your inventory in check, helping you manage stock levels, orders, and deliveries more efficiently.

- Van Sales and Fleet Management: Van sales software and fleet management software are invaluable tools to streamline sales and delivery operations, reducing costs and improving customer service.

- Attendance Management: Attendance management software ensures that your workforce is efficiently managed, contributing to better overall business management.

By integrating these modern tools, you not only optimise production but also streamline various facets of your business, from inventory and procurement to sales and workforce management. They are the key to unlocking your manufacturing potential and ensuring a competitive edge in the industry with more efficient and productive automation in manufacturing operations.

In other words, the right tools are essential for business success.

In the digital age, modern tools can empower your team, streamline tasks, foster innovation, boost motivation, and lead to higher productivity and better results in automation in manufacturing.

To stay competitive, it’s crucial to invest in the tools that will drive your team and business forward.

If you are confused about which tool or software to use, check out Rapidor.

By integrating Rapidor’s solutions into your processes, you can transform your team’s potential and lay the foundation for business success.

Don’t let outdated tools hold your team back.

Explore Rapidor’s suite of modern tools today!