Stock management is a critical aspect of the Fast-Moving Consumer Goods (FMCG) industry, where efficiency and agility are paramount. Effective stock management ensures a seamless flow of goods from production to the hands of consumers, optimizing inventory levels, and minimizing costs. In the dynamic FMCG sector, where demand can fluctuate rapidly, proper stock management is essential to meet customer expectations and stay ahead of competitors.

However, the FMCG industry faces unique challenges that make stock management a complex endeavor. With rapid inventory turnover, seasonal demands, multi-channel distribution, and expiry date management, FMCG companies must employ innovative strategies and leverage technology to maintain optimal stock levels and enhance supply chain efficiency. In this blog, we will explore the distinctive challenges of stock management in the FMCG industry and discuss best practices and essential software features to overcome them successfully.

The Unique Challenges of Stock Management in FMCG

Rapid Inventory Turnover

Rapid inventory turnover refers to the rate at which products move off the shelves and are replaced by new stock. In the FMCG industry, where products have a short shelf life and consumer demands can change swiftly, managing inventory turnover becomes crucial. A high inventory turnover rate indicates that products are selling quickly, ensuring minimal wastage and maximizing revenue. However, it also poses challenges as stock decisions need to be made promptly and accurately to avoid stockouts and meet fluctuating demand. Employing real-time data analytics and advanced forecasting techniques becomes essential in optimizing inventory levels and maintaining a delicate balance between supply and demand.

Seasonal Demands & Fluctuations

Seasonal demands and fluctuations are common occurrences in the FMCG industry. For instance, during festivals, holidays, or special events, certain products experience a surge in demand, while at other times, sales may drop. Managing these fluctuations efficiently is vital to prevent stockouts or overstocking. A well-implemented flexible stock management system can cater to seasonal demands by adjusting inventory levels based on historical data and predictive analytics. By accurately anticipating demand patterns, FMCG companies can optimize production and distribution, ensuring adequate stock during peak periods and avoiding excess inventory during lean periods.

Multi-channel Distribution

The evolving nature of FMCG distribution has become increasingly complex with the rise of multiple sales channels. Traditionally, FMCG products were primarily distributed through physical retail stores. However, the advent of e-commerce, direct-to-consumer (D2C) channels, and third-party platforms has diversified the distribution landscape. This multi-channel approach offers greater market reach and convenience for consumers. Nevertheless, managing stock across various channels requires synchronization and efficient tracking. A robust stock management system with multi-channel capabilities can centralize inventory data, allowing real-time monitoring and accurate stock allocation to meet the demands of different distribution channels.

Expiry Date Management

In the FMCG industry, products with limited shelf life must be carefully monitored and managed to avoid wastage and consumer dissatisfaction. Expiry date management is a critical aspect of stock management, particularly for perishable goods like food and beverages, personal care products, and medicines. FMCG companies need to ensure that products are sold before their expiration date to maintain quality and comply with regulatory requirements. Implementing a reliable stock management system that incorporates expiry date tracking enables timely rotation of stock, minimizing the risk of product spoilage and maintaining consumer trust in the brand.

Best Practices in Stock Management for FMCG

Forecasting & Demand Prediction

Accurate forecasting and demand prediction play a pivotal role in FMCG stock management. Understanding consumer preferences and market trends enables businesses to anticipate future demand and plan inventory levels accordingly. Historical data analysis, advanced analytics, and machine learning algorithms are effective methods for improved predictions. By leveraging past sales data, seasonal patterns, and market insights, FMCG companies can optimize stock levels, reduce excess inventory, and minimize stockouts. This ensures better utilization of resources and enhances customer satisfaction through timely product availability.

First-In-First-Out (FIFO) Strategy

The First-In-First-Out (FIFO) strategy is a fundamental approach in FMCG stock management, especially for products with limited shelf life. Under this method, the oldest inventory is sold or distributed first, ensuring that products do not expire or lose freshness. Implementing FIFO is significant as it reduces the risk of products becoming obsolete or unsellable. In the FMCG industry, where product quality and consumer trust are paramount, adhering to the FIFO principle ensures that consumers receive fresh and unexpired goods, contributing to positive brand perception.

Regular Audits & Cycle Counts

Regular audits and cycle counts are essential practices to maintain accurate stock data and identify discrepancies in inventory records. These checks help businesses detect stock inaccuracies, such as pilferage, shrinkage, or data entry errors. The frequency of audits depends on the size and complexity of the FMCG operation but should be conducted regularly to prevent inaccuracies from accumulating and affecting decision-making. By consistently reviewing stock levels, FMCG companies can take corrective actions promptly, ensure data integrity, and maintain an efficient supply chain.

Efficient Return Management

Managing returns effectively is vital in the FMCG industry to minimize losses and maintain customer satisfaction. Efficient return management involves establishing clear return policies, tracking the reasons for returns, and handling returned products efficiently. Implementing a reverse logistics process ensures that returned products are assessed, processed, and either restocked or disposed of appropriately. By understanding the reasons for returns, FMCG companies can identify product quality issues, packaging concerns, or supply chain inefficiencies and take corrective measures to reduce return rates and enhance overall product performance.

Supplier Relationship Management

Supplier relationship management is crucial in the FMCG sector as it directly impacts product quality, availability, and pricing. Building strong and collaborative partnerships with suppliers ensures a steady and reliable supply of raw materials or finished products. Maintaining good relations with suppliers fosters mutual trust and support during challenging times. Benefits of effective supplier relationship management include improved cost negotiation, preferential treatment during demand surges, access to innovative products, and reduced lead times. In the competitive FMCG industry, a robust supplier relationship management strategy contributes to seamless stock replenishment and operational efficiency.

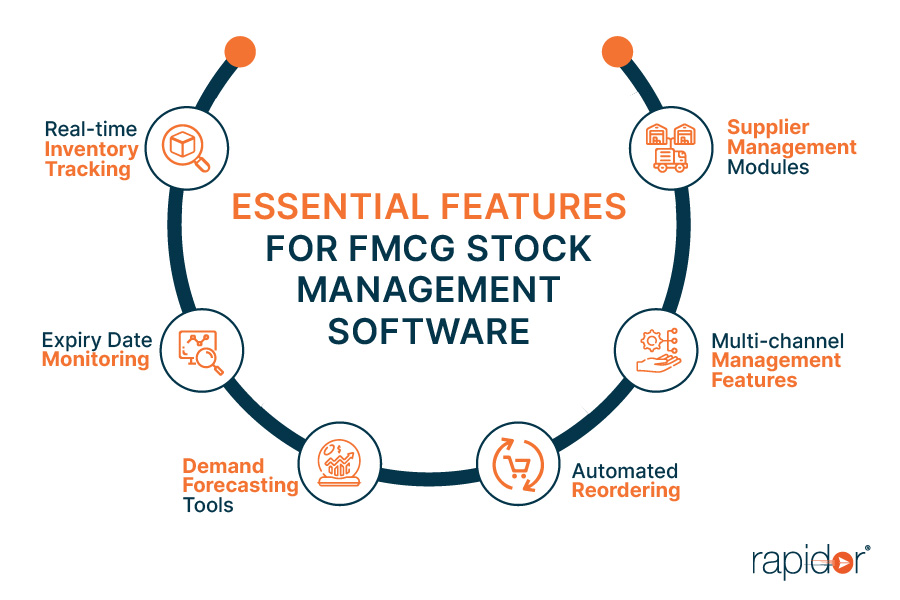

Essential Software Features for FMCG Stock Management

Real-Time Inventory Tracking

Real-time inventory tracking is a critical feature in FMCG stock management as it provides immediate visibility into stock levels and movement. With the fast-paced nature of the FMCG industry, real-time data allows businesses to make informed decisions promptly. This feature addresses rapid inventory turnover by keeping managers updated on stock levels, enabling timely reordering and minimizing the risk of stockouts. It also aids in identifying slow-moving or obsolete products, facilitating better inventory optimization and reducing carrying costs. By having accurate and up-to-date inventory information, FMCG companies can ensure that products are available when and where they are needed, meeting customer demands efficiently.

Expiry Date Monitoring

Expiry date monitoring is a crucial feature to track product expiration dates and ensure the sale of fresh and safe products. The software should allow users to record and manage expiry dates for each batch of products. By setting up alerts for approaching expirations, FMCG businesses can take proactive actions, such as offering discounts or recalling products, to prevent potential losses due to expired inventory. Effective expiry date monitoring enhances product quality, reduces waste, and safeguards brand reputation, as customers receive products with extended shelf life, leading to increased customer satisfaction and loyalty.

Multi-channel Management Features

Integrated multi-channel management features are essential for FMCG stock management due to the diverse distribution channels in the industry. The software should provide a centralized platform to manage inventory across various sales channels, such as physical stores, online marketplaces, and wholesale distributors. This integrated approach streamlines stock tracking, order fulfillment, and demand forecasting. Features to look for include seamless synchronization of inventory data, real-time stock updates across channels, and automated order processing. Multi-channel management ensures efficient stock allocation, prevents overselling, and optimizes inventory utilization, enabling FMCG businesses to deliver a consistent and smooth shopping experience to customers across all channels.

Demand Forecasting Tools

Demand forecasting tools powered by AI and machine learning are revolutionizing FMCG stock management. These tools analyze historical sales data, customer behavior, market trends, and external factors to predict future demand accurately. By understanding demand patterns, FMCG companies can align their inventory levels with anticipated sales, reducing excess inventory and associated costs. Effective forecasting tools help optimize stock replenishment, minimize stockouts, and prevent overstocking. Some software also offers scenario-based simulations to evaluate the impact of changing market conditions on inventory requirements. FMCG businesses can make data-driven decisions, increase operational efficiency, and ensure the right products are available at the right time and in the right quantities.

Automated Reordering

Automated reordering is of utmost significance in FMCG stock management to maintain optimal stock levels and prevent stockouts. The software should automate the reordering process based on predefined thresholds and demand forecasting data. When inventory levels reach a predetermined minimum, the system generates purchase orders or replenishment requests to suppliers automatically. Key features to look for include customizable reorder points, integration with supplier databases, and the ability to adjust reorder quantities based on demand fluctuations. Automated reordering enhances supply chain efficiency, reduces the risk of stockouts, and frees up valuable time for inventory managers to focus on strategic planning and decision-making.

Supplier Management Modules

Supplier management modules in FMCG stock management software facilitate seamless communication and collaboration with suppliers. These modules allow businesses to maintain supplier profiles, track supplier performance, and monitor purchase orders and deliveries. By streamlining supplier interactions, FMCG companies can strengthen supplier relationships, negotiate better terms, and ensure a steady and reliable supply of goods, contributing to enhanced stock management efficiency.

Conclusion

The FMCG industry is witnessing a paradigm shift in stock management practices, driven by the growing role of technology and software solutions. As the industry continues to evolve, it becomes imperative for FMCG businesses to embrace advanced stock management tools to stay competitive and meet customer demands efficiently.

The adoption of real-time inventory tracking, expiry date monitoring, multi-channel management features, demand forecasting tools, automated reordering, and supplier management modules empowers FMCG companies with greater control and visibility over their supply chains.

Emphasizing the role of tech and software, these tools enable data-driven decision-making, reduce operational inefficiencies, optimize inventory levels, and enhance customer satisfaction. As FMCG businesses face dynamic challenges and opportunities, investing in robust stock management software becomes a strategic imperative to remain agile and resilient in an ever-changing marketplace.

We encourage FMCG businesses to embrace these innovative practices and tools to unlock their full potential, adapt to market fluctuations, and achieve sustainable growth in the exciting future of stock management in the FMCG industry.

FAQ

1. What is the FMCG industry and why is stock management crucial for it?

The Fast-Moving Consumer Goods (FMCG) industry comprises companies that produce and distribute everyday products that sell quickly and at relatively low costs, such as food, beverages, personal care, and household products. Stock management is pivotal for FMCG businesses because of the rapid turnover of products, the perishable nature of many items, and the need to meet fluctuating demand without incurring significant holding costs.

2. How do seasonal demands impact stock management in FMCG?

Seasonal demands lead to peaks and troughs in product requirements at different times of the year. For instance, sunscreen might see a surge in demand during summer, while demand for certain beverages might increase during festive seasons. Proper stock management ensures that FMCG businesses can meet these varying demands efficiently without overstocking or facing stockouts.

3. What role does technology play in modern FMCG stock management?

Technology, especially stock management software, plays a pivotal role in modern FMCG stock management. It offers real-time inventory tracking, demand forecasting tools, automated reordering, and multi-channel management features. By utilizing technology, FMCG businesses can optimize their stock levels, reduce waste, and improve their responsiveness to market changes.

4. Why is the First-In-First-Out (FIFO) strategy significant in FMCG stock management?

The FIFO strategy, which ensures that the oldest inventory items are sold first, is especially important in FMCG due to the perishable nature of many products. By following a FIFO approach, businesses can reduce the chances of products reaching their expiration date before being sold, thus minimizing waste and potential losses.

5. How do stock management software tools handle product expiration?

Modern stock management software tools often come with expiry date monitoring features. These tools automatically track the shelf life of products, sending alerts when products are nearing their expiration dates. This assists businesses in prioritizing the sale of these products or relocating them to higher-demand areas, thus mitigating the risk of unsold expired goods.