In today’s dynamic business landscape, managing inventory efficiently is paramount for small to medium enterprises.

But what exactly does it mean when we talk about stockouts and overstock? How does one strike a balance, ensuring that products are always available to meet customer demands without unnecessarily tying up capital in excess stock?

As we delve deeper into this guide, we’ll unravel the intricacies of advanced inventory management techniques. From demand forecasting to embracing the capabilities of stock management software, we aim to arm business owners with the necessary tools and strategies.

This will help keep their inventory balanced, efficient, and aligned with market demands.

What is Stockouts vs. Overstock? Understanding the Basics

Stockouts refer to situations where a business runs out of inventory for a particular item, unable to meet the demand from customers.

It’s like reaching into a cookie jar and finding it empty when you’re craving a treat. Not only are stockouts detrimental to customer satisfaction, but they also translate to lost sales and can tarnish a business’s reputation.

On the other hand, overstock represents the opposite end of the spectrum.

It’s when businesses hold more inventory than they can sell in a foreseeable duration. Imagine having a cookie jar overflowing with treats, but they start to go stale before they can be consumed.

Overstocking ties up valuable resources in the form of unsold goods, incurs storage costs, and even risks product obsolescence.

In essence, both these scenarios underscore the significance of optimal inventory management. It acts as the backbone of retail and manufacturing businesses, impacting everything from cash flow to customer satisfaction.

Efficient inventory management software not only helps in tracking inventory levels but also provides invaluable insights into consumer behaviour and sales trends.

What are the Challenges Ahead?

The pain points associated with stockouts and overstock aren’t mere theoretical problems. They’re real challenges that business owners grapple with daily.

Missed sales opportunities, heightened storage expenses, diminished cash flow, and wavering customer loyalty – these are just a few repercussions of not getting inventory management right.

What are the Risks of Poor Inventory Management?

Managing inventory isn’t just about having products on shelves or in warehouses. It’s a critical element of business operations that, if overlooked, can lead to significant repercussions.

Let’s delve deeper into the risks associated with poor inventory management.

What are the financial Implications of Stockouts and Overstock?

Missed Sales Opportunities

A direct consequence of stockouts is the loss of sales.

When customers cannot find what they’re looking for, they often turn to competitors. The sales you miss not only affect the present transaction but also potential future transactions if the customer decides to switch loyalty.

Increased Operational Costs

Overstock translates to more products in storage, leading to higher warehousing costs.

From utilities to personnel salaries, businesses find themselves shouldering unnecessary costs, which could have been avoided with better stock management software.

Cash Flow Constraints

Money tied up in excess stock is money that isn’t available for other investments or operational needs. It’s a ripple effect—by over-purchasing inventory, businesses might miss out on other growth opportunities or even struggle with day-to-day expenses.

Product Obsolescence and Wastage

Products, especially perishable items or those in industries with fast technological advancements, can become obsolete if left unsold for extended periods. This leads to markdowns or even complete write-offs, impacting the bottom line.

What are the impacts on Customer Satisfaction and Business Reputation?

Damaged Brand Loyalty

Stockouts can be incredibly frustrating for customers.

When they can’t find what they’re looking for, especially if it’s a recurring problem, they might question their loyalty to the brand. With numerous competitors at the ready, it’s easy for customers to switch allegiances.

Reputation Takes a Hit

Word-of-mouth, both online and offline, plays a crucial role in shaping a business’s reputation.

Unsatisfied customers, due to stockouts or receiving obsolete products from overstock, are more likely to share their negative experiences. In the age of online reviews and social media, such complaints can spread rapidly, tarnishing a brand’s image.

Diminished Customer Experience

Modern customers expect seamless shopping experiences. When faced with stockouts, their journey is disrupted.

Even if they decide to wait for restocks or opt for an alternative product, the experience is tainted. Effective inventory management ensures that customer experiences are smooth and fulfilling.

In the rapidly evolving business world, where customer demands shift and competitors are always on the lookout for a slip, poor inventory management can be a costly oversight. It’s not just about financial losses; it’s about jeopardising the very reputation and trustworthiness of your brand.

That’s why implementing robust inventory management software and strategies is more than an operational necessity—it’s a strategic imperative for business growth and sustainability.

What are the Strategies to Avoid Stockouts?

Navigating the turbulent waters of inventory management can be challenging, but with the right strategies in place, businesses can steer clear of stockouts and ensure product availability.

Here are some pivotal strategies, backed by inventory management software and best practices, that can make a tangible difference.

How to Forecast Demand Accurately?

The foundation of effective inventory management lies in accurately predicting customer demand. By understanding future sales patterns, businesses can stock up appropriately.

Here’s how to enhance demand forecasting:

Historical Data Analysis

Dive into past sales records, looking for trends, seasonal patterns, and growth trajectories. Advanced inventory management software can offer insights, collate data, and even provide predictive analytics to guide decision-making.

Market Research

Regularly survey the market, your competitors, and customer preferences. Such insights can help you anticipate shifts in demand and adapt accordingly.

Stay Informed on Industry Trends

Be aware of industry events, product launches, or any global happenings that could influence your sales patterns.

What is the Role of Safety Stock?

Safety stock acts as a buffer, an extra quantity of inventory held to guard against stockouts caused by unpredictable shifts in demand or supply delays.

Calculate Optimal Levels

Utilise inventory management software to calculate the right amount of safety stock. Consider factors like average demand, lead time, and past variability in demand and supply.

Regularly Review Safety Stock Levels

As demand patterns change, safety stock levels should be revisited and adjusted accordingly.

What are the benefits of Real-time Tracking of Inventory?

Being informed about your stock levels in real-time is pivotal to preventing stockouts.

Integrate Systems

Ensure your point-of-sale (POS) system, warehouse management, and online channels are integrated. With synchronised stock management software, businesses can have a holistic view of inventory levels across all channels.

Automated Alerts

Set up alerts to be notified when stock reaches a certain threshold. This gives businesses ample time to restock and ensures they’re never caught off guard.

What is the Importance of Supplier Relationships?

Building a strong relationship with suppliers isn’t just about getting the best prices. It’s about ensuring consistency in product availability.

Open Communication Channels

Establish regular communication with suppliers. Discussing forecasts, sharing sales data, or simply communicating more can lead to smoother operations.

Diversified Supplier Base

Relying on a single supplier can be risky. By diversifying the supplier base, businesses can mitigate risks associated with supply chain disruptions.

Negotiate Better Terms

With strong supplier relationships, businesses can negotiate terms like shorter lead times, which directly impact how quickly inventory can be replenished.

By implementing these strategies, backed by robust inventory management software, businesses can take proactive steps to prevent stockouts.

Strategies to Avoid Overstock

Overstocking isn’t just a matter of using up valuable storage space; it represents tied-up capital, increased holding costs, and the risk of product obsolescence.

Let’s dive into strategies, supplemented by the capabilities of inventory management software, to keep overstocking in check.

What is the Inventory Turnover Ratio? Understanding and Improving It

The Inventory Turnover Ratio is a metric that measures how many times a business sells and replaces its inventory over a certain period, typically a year.

A higher turnover indicates optimal sales and efficient inventory management, while a lower turnover might signal overstocking or issues with product desirability.

How to Improve the Inventory Turnover Ratio?

Dynamic Pricing Strategies

Adjusting prices based on demand, seasons, or promotional activities can help move stock faster, thus increasing the turnover ratio.

Product Promotions

Offering limited-time discounts or bundling products can increase sales and prevent old stock from lingering.

Stock Variety

Ensure you’re not just diversifying, but also stocking what sells. Use inventory management software to analyse product performance and adjust your stock profile accordingly.

How to Use Just-In-Time (JIT) Inventory Methods?

This method revolves around ordering inventory only when it’s needed for production or sales, reducing the amount of stock held at any given time.

What are the Benefits of JIT?

Reduced Holding Costs

By ordering stock only when required, businesses can significantly cut down on storage and holding costs.

Minimised Waste

JIT reduces the risk of perishable goods expiring or products becoming obsolete.

Optimised Cash Flow

With less money tied up in unsold stock, businesses can allocate funds to other operational needs or growth opportunities. However, JIT requires accurate demand forecasting and strong supplier relationships, as delays can lead to stockouts.

How to Implement an Inventory Audit?

Periodic inventory audits, whether they’re done annually or more frequently, can provide a clearer picture of what’s on hand versus what’s on the books.

Here’s why they’re essential:

Accuracy

Audits ensure that the stock data in your inventory management software mirrors the actual stock. Discrepancies can highlight issues like theft, misplacement, or data-entry errors.

Decision-making

Regular audits provide insights that can guide purchasing decisions, helping businesses understand which products are slow-moving and which ones are in demand.

Financial Reporting

Accurate inventory data is crucial for financial reporting and can influence a business’s valuation, tax obligations, and profit metrics.

How can you Leverage Technology?

In an era where digital transformation is revolutionising businesses across sectors, the domain of inventory management is no exception.

The integration of technology not only streamlines operations but also provides actionable insights to keep stock levels optimal. Let’s delve into the capabilities of Inventory Management Systems (IMS) and how they’re changing the landscape.

What are Inventory Management Systems (IMS)?

Inventory Management Systems (often abbreviated as IMS) are sophisticated software platforms or suites. They are designed to monitor, control, and optimise inventory levels, orders, sales, and deliveries.

By replacing manual inventory checks and guesswork, IMS offers a more accurate, efficient, and time-saving approach to keeping track of stock.

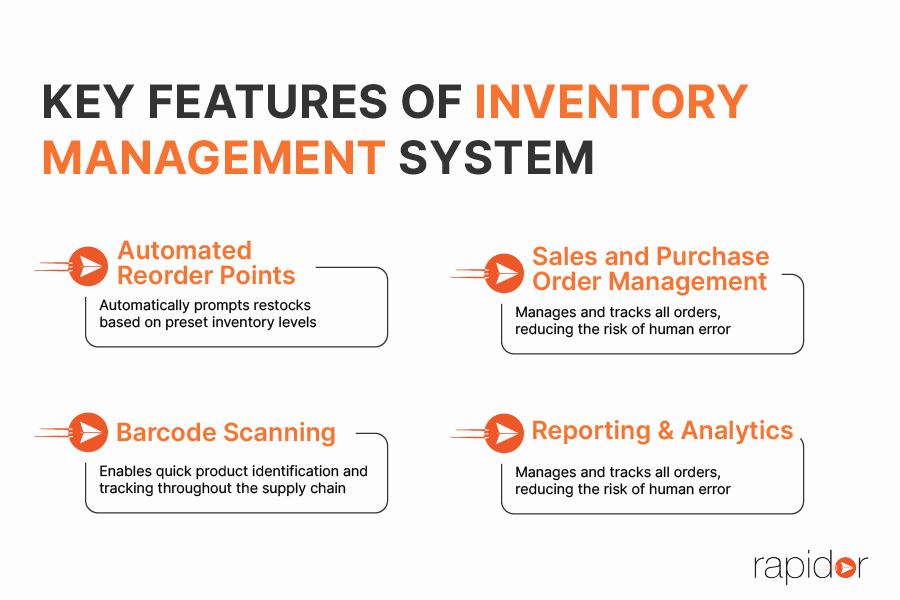

What are the Key Features of Inventory Management System?

Barcode Scanning

Enables quick product identification and tracking throughout the supply chain.

Automated Reorder Points

Automatically prompts restocks based on preset inventory levels.

Sales and Purchase Order Management

Manages and tracks all orders, reducing the risk of human error.

Reporting & Analytics

Provides insights into sales trends, product performance, and inventory metrics to guide business decisions.

How Technology Automates and Simplifies Inventory Management?

Real-time Data Access

With modern IMS platforms, businesses can access real-time inventory data, ensuring that stock levels across various channels (in-store, online, warehouses) are consistently updated and synchronised.

Minimising Human Error

Manual stock checks, order placements, and sales tracking are prone to errors. Inventory management software automates these processes, reducing mistakes and ensuring accurate stock counts.

Demand Forecasting

Leveraging historical sales data and analytics, many IMS tools can predict future demand patterns. Such predictive insights can be invaluable in preparing for seasonal demands or spotting market trends early on.

Centralised Control

For businesses operating across multiple locations or sales channels, an IMS provides a centralised system to manage inventory. Whether it’s transferring stock between locations or ensuring consistent pricing across platforms, IMS brings cohesion to inventory management.

Seamless Integration

Modern IMS platforms often integrate seamlessly with other business tools like Point-of-Sale systems, e-commerce platforms, and Customer Relationship Management tools. This holistic integration ensures a consistent flow of data across systems.

Conclusion

Inventory management is far from a mundane, background task; it’s a strategic function that can make or break a business’s success.

As we’ve explored, poor inventory management can lead to both stockouts and overstocks, each with their financial implications, impacts on customer satisfaction, and potential dents to business reputation.

We’ve highlighted the imperative strategies businesses should employ – demand forecasting, safety stock & JIT, real-time inventory tracking & audits. Along with that you should focus on building supplier relationships and leverage technology.

Embracing Inventory Management Systems (IMS) is more than a nod to modernity—it’s a strategic move towards efficiency, accuracy, and profitability.

A reactive approach to inventory management leaves businesses perpetually playing catch-up, often leading to hurried decisions and missed opportunities. A proactive stance, underpinned by the strategies we’ve discussed and ably supported by inventory management software, places businesses a step ahead.

It ensures they’re prepared for demand surges, equipped to handle supply chain disruptions, and are consistently offering customers what they want, when they want it.