In this era of data-driven decision-making, predictive analytics emerges as the beacon of hope for fleet managers. Integrating predictive analytics into fleet management software offers a promising solution to the longstanding issue of operational downtime.

This technology not only identifies potential maintenance concerns before they escalate but also provides actionable insights to address them in a timely manner.

In the fast-paced and ever-evolving world of logistics and fleet management, ensuring smooth operations is of paramount importance. Fleet managers, operations directors, and C-level executives constantly grapple with the intricate challenges posed by fleet maintenance.

These challenges are not merely logistical but have a significant financial implication. The cost of operational downtime, stemming from unexpected vehicle breakdowns or unanticipated maintenance issues, can be staggering.

As we delve deeper into this topic, we will uncover the transformative potential of predictive analytics in fleet care. From enabling proactive maintenance scheduling to realising significant cost savings, the integration of predictive analytics into fleet management software is set to redefine the benchmarks of operational excellence.

What is the Cost of Operational Downtime?

Operational downtime in fleet management isn’t just about a vehicle being off the road. It’s about the cascading effects that a single vehicle’s downtime can have on the entire logistics operation.

When a vehicle breaks down unexpectedly, it disrupts the schedule, resulting in missed delivery windows, potential contract penalties, and a dent in the company’s reputation. Furthermore, emergency repairs tend to be more expensive than scheduled maintenance, further escalating the costs.

Delays in deliveries, loss of customer trust, and increased maintenance costs are just a few repercussions of such downtimes. But what if there was a way to foresee these challenges and make informed decisions to prevent them?

Is Predictive Analytics the Future of Fleet Care?

Predictive analytics, at its core, uses historical data to forecast future events. In the context of fleet management, this means analysing data from various vehicle sensors, maintenance logs, and other relevant sources to predict potential maintenance needs.

By spotting patterns and trends, predictive analytics can forewarn fleet managers about impending issues, allowing them to act proactively rather than reactively.

Incorporating predictive analytics into fleet management software is akin to giving fleet managers a crystal ball – one that provides a data-driven glimpse into the future health of their fleet. Such foresight can be invaluable in planning maintenance schedules, allocating resources efficiently, and ensuring that vehicles remain on the road, delivering goods and services without interruption.

The Basics of Predictive Analytics in Fleet Management

What is Predictive Analytics?

Predictive analytics is a sophisticated method that harnesses the power of data to forecast future outcomes. By analysing vast amounts of historical data, it can identify patterns and trends that can be indicative of future events.

In simpler terms, think of it as the ability to predict tomorrow’s weather based on the patterns observed over the past month or year. But instead of predicting rain or shine, in the world of fleet management, we’re forecasting potential vehicle failures, wear and tear, and maintenance needs.

What is the Difference between Traditional Fleet Management vs. Predictive Analytics?

Traditional fleet management has largely been reactive. Vehicles were typically maintained based on set schedules or in response to a breakdown or noticeable issue. For instance, a truck might be serviced every 10,000 miles or when a specific problem arises.

This approach, while straightforward, has inherent inefficiencies. Servicing might occur too early, leading to unnecessary costs, or too late, resulting in breakdowns and operational downtime.

In contrast, predictive analytics in fleet management software brings a proactive approach. Instead of relying on generalised schedules or waiting for a problem to manifest, predictive analytics evaluates the actual condition of each vehicle based on real-time data. This data-driven method offers several advantages:

Early Detection

By monitoring vehicle health in real-time, predictive analytics can detect issues long before they become critical problems. This early detection means repairs can be made when they are minor, avoiding costly major overhauls or replacements.

Optimised Maintenance Schedules

With predictive analytics, maintenance can be scheduled when it’s truly needed, based on the vehicle’s actual condition and performance metrics. This not only reduces unnecessary maintenance costs but also ensures that vehicles are always in optimal condition, leading to longer asset lifespans.

Reduced Operational Downtime

One of the standout benefits of predictive analytics is the significant reduction in unexpected breakdowns. By forecasting and addressing issues before they escalate, vehicles experience less downtime, ensuring smooth operations and cost savings for the organisation.

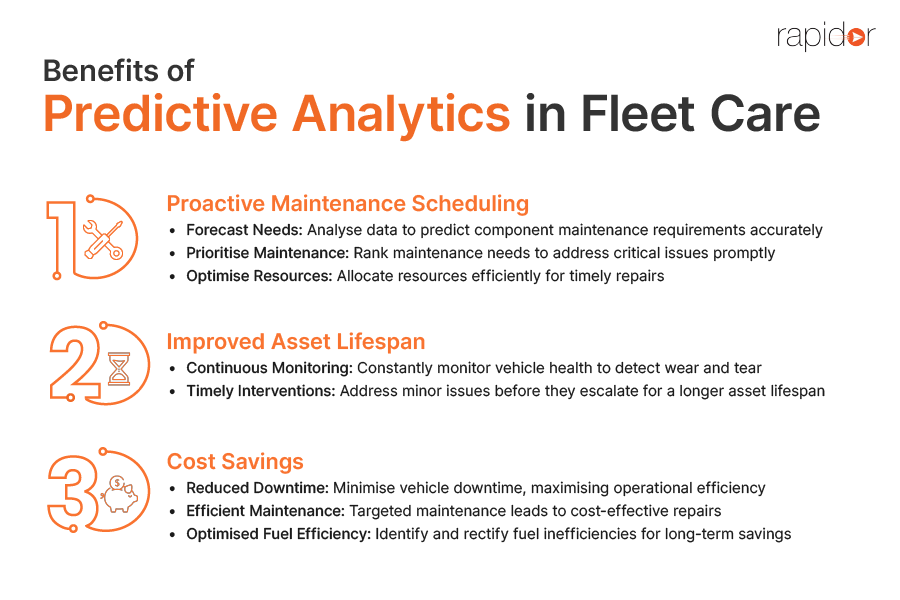

What are the Benefits of Predictive Analytics in Fleet Care?

As logistics and fleet management complexities continue to grow, businesses are on the constant lookout for transformative solutions that can optimise their operations. Predictive analytics, when seamlessly integrated into fleet management software, offers a slew of benefits that address some of the most pressing challenges in the industry. Let’s explore the manifold advantages that predictive analytics brings to fleet care.

Proactive Maintenance Scheduling

Traditionally, maintenance was often dictated by set schedules or prompted by glaring issues. This reactive approach led to inefficiencies, as vehicles were sometimes serviced either too early, incurring unnecessary expenses, or too late, resulting in breakdowns.

With predictive analytics, the narrative changes dramatically. Fleet management can now:

Forecast Needs

By analysing historical and real-time data, predictive analytics can accurately forecast when specific components of a vehicle might require attention.

Prioritise Maintenance

Not all maintenance requirements are of the same urgency. Predictive analytics can rank these needs, ensuring critical issues are addressed promptly, reducing the risk of major breakdowns.

Optimise Resources

By knowing which vehicles need maintenance and when, resources—both in terms of manpower and equipment—can be optimally allocated. This ensures no vehicle is left waiting for extended periods and repairs are conducted efficiently.

Improved Asset Lifespan

Every vehicle in a fleet represents a significant capital investment. Ensuring that these assets last as long as possible and in the best possible condition is a top priority for fleet managers.

Continuous Monitoring

Predictive analytics continuously monitor every vehicle’s health. This constant vigilance ensures that wear and tear, which might otherwise go unnoticed, is promptly addressed.

Timely Interventions

With data-driven insights, minor issues can be resolved before they snowball into major problems. By addressing problems in their nascent stages, the overall strain on the vehicle is reduced, leading to a longer and more efficient operational life.

Cost Savings

The economic implications of integrating predictive analytics into fleet care cannot be overstated. This advanced approach directly translates to tangible cost savings in multiple ways:

Reduced Downtime

As the old adage goes, “time is money.” Every hour a vehicle is down, especially due to unexpected issues, it’s a cost to the business. Predictive analytics minimises these downtimes, ensuring vehicles spend more time on the road than in the workshop.

Efficient Maintenance

Targeted and timely maintenance often means that repairs are less extensive and less expensive. By acting on predictive insights, fleets can avoid the hefty costs associated with major overhauls or replacements.

Optimised Fuel Efficiency

Continuous monitoring can also highlight inefficiencies in fuel consumption. Addressing these can lead to better fuel economy, resulting in significant savings over time.

How to Implement Predictive Analytics in Fleet Management Software?

As the logistics world increasingly recognizes the transformative potential of predictive analytics in fleet care, many companies are eager to integrate this powerful tool into their operations. However, the implementation process can seem daunting.

Fear not, for we have curated a step-by-step guide to ensure a smooth transition, integrating predictive analytics into your existing fleet management systems seamlessly.

Why Should You Assess the Current Infrastructure?

Before diving into the integration, evaluate your existing fleet management system. Identify its strengths, limitations, and the kind of data it collects. This assessment will provide clarity on compatibility issues and the extent of upgrades needed for predictive analytics.

How Important is Data Collection & Integration?

Predictive analytics thrives on data. Ensure your fleet vehicles are equipped with the necessary sensors and IoT devices to capture real-time data. Integrate this data flow with your fleet management software, ensuring there’s a system in place to store, manage, and analyse this data effectively.

How to Choose the Right Predictive Analytics Tool?

There are numerous predictive analytics tools available in the market, each with its unique features and capabilities. Consider the following when making a choice:

- Compatibility with existing fleet management software.

- Scalability to accommodate fleet growth.

- Functionality that aligns with your specific fleet needs.

- Ease of Use to ensure your team can adapt without a steep learning curve.

Collaborate with Experts; Does it Help?

It’s beneficial to have data scientists or predictive analytics experts on board. Their expertise will be invaluable in setting up the algorithms, understanding the data, and fine-tuning the system for optimal results. If hiring in-house experts isn’t feasible, consider consulting or partnering with specialised firms.

What is the Importance of Training and Development?

With the system in place, it’s crucial to train your fleet management team to use the new tools effectively. This includes understanding the insights provided, making informed decisions based on predictions, and optimising proactive maintenance scheduling. Continuous training ensures that your team stays updated with any advancements or changes in the analytics tool.

Is Continuous Monitoring and Optimization Needed?

Once implemented, it’s essential to continuously monitor the predictive analytics system. This isn’t a ‘set and forget’ solution. Algorithms might need adjustments, new data sources could emerge, and fleet requirements may evolve. Regularly review the system’s performance, ensuring it provides accurate predictions and offers the desired cost savings.

What is the Feedback Loop?

Create a feedback loop where the fleet management team can report back on the accuracy and usefulness of the predictive insights. This feedback is invaluable for refining algorithms and ensuring the system remains aligned with on-ground realities.

Why Should You Stay Updated?

The world of predictive analytics is ever-evolving. Stay abreast of the latest developments, advancements, and best practices.

This proactive approach ensures that your fleet management system remains state-of-the-art, continually reaping the benefits of the latest innovations.

Incorporating predictive analytics into fleet management software is a journey of transformation. While the process might require investment in terms of time, resources, and training, the dividends it pays in improved efficiency, reduced downtime, and substantial cost savings. This makes it an indispensable tool for modern fleet management.

With the right steps and a strategic approach, your fleet operations can be future-proofed, ready to conquer the challenges of tomorrow.

What Does Future Fleet Management Look Like?

In the intricate world of fleet management, the pursuit of operational excellence is a relentless journey. Every minute lost to vehicle downtime, every inefficiency in maintenance scheduling, and every unplanned expenditure adds up, affecting the bottom line.

However, the advent of predictive analytics in fleet care marks a significant turning point in this journey. By harnessing the power of data-driven insights, predictive analytics not only promises but delivers a proactive approach to fleet management.

Gone are the days of reactive maintenance and the uncertainties of unplanned operational downtime. With the capability to forecast potential vehicle issues, optimise maintenance schedules based on real-time data, and significantly extend asset lifespans, the transformative potential of predictive analytics is undeniable.

The benefits are manifold: from tangible cost savings to the less quantifiable, yet equally crucial, enhancement of reputation owing to improved reliability and efficiency. Every facet of fleet management stands to gain, with the overarching outcome being a significant reduction in operational downtime.

What Can You Do?

If you’re on the fence about integrating predictive analytics into your fleet management system, consider this: In an industry where time, efficiency, and reliability are of paramount importance, can you afford not to harness the power of foresight that predictive analytics offers?

We urge you to delve deeper, explore predictive analytics solutions tailored for fleet management, and embark on a transformative journey. Equip your fleet operations with the tools of tomorrow, ensuring a competitive edge in an ever-evolving landscape.